At Ballard, our mission is to Deliver Fuel Cell Power for a Sustainable Planet.

And we are succeeding: across the globe, Ballard-powered buses, trains, trucks, and soon boats are displacing thousands of diesel and gas engines. Our products are lowering global GHG gas emissions, and increasing the livability of urban areas by helping to enable the transition to vehicles with zero tailpipe emissions.

But there is more to sustainability than deploying zero-emission vehicles. For the complete picture, we have to look into our total environmental impact, from our operational carbon footprint to the cradle-to-grave greenhouse gas impacts of fuel cell-powered electric vehicles.

Ballard’s 2020 ESG Report: Progress on the road to carbon neutrality

Our newly released 2020 ESG Report is a comprehensive document that details our sustainability performance, including our goal of becoming carbon neutral by 2030. The report addresses our progress in measuring and reducing the lifecycle environmental impacts of our technologies, including:

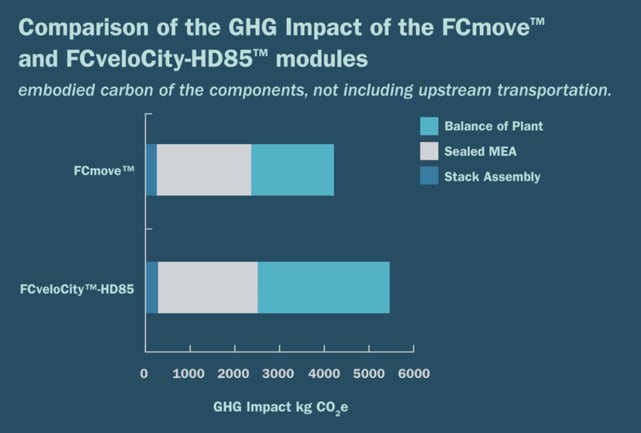

- “Cradle-to-gate” greenhouse gas assessments of our products, which document the carbon footprint of our fuel cell stacks and heavy-duty power modules from the extraction and processing of raw materials to the manufacturing and assembly of the power module. These studies identify the major sources of our products’ embodied CO2 emissions, which will guide us in further reductions.

- Our corporate GHG inventory, developed annually with Offsetters Clean Technology, which helps us quantify, track and reduce the carbon footprint of our operations in Canada and Europe.

Data shows an 11% reduction in our corporate carbon footprint from 2019 to 2020.

Committed to sustainable manufacturing and products

Our primary mission is to enable a worldwide reduction of dependence on high-emission diesel and gas engines. But we also need to ensure our zero-emission powertrains are developed sustainably. So we focus on our internal procedures and technologies, to minimize our GHG impacts from “cradle-to-gate”.

GHGs reduced by 6%

Sustainability is a priority in product development at Ballard, just as important as performance enhancements and cost reduction. As reported in the 2020 ESG Report, the latest generation of our heavy-duty power module produces 1.2 metric tons less of GHGs than previous designs. That’s roughly equivalent to driving an average passenger car 5,000 kilometers – all achieved through product design efforts.

The new design of FCmove™-HD contains 50% fewer components and less platinum, while delivering the same reliable, robust performance to power buses and trucks. Its cradle-to-gate GHGs total 5,172 kg of carbon dioxide equivalent (kgCO2e), which is 1,243 kgs CO2e less than the previous generation FCveloCity™-HD85.

Recycling and refurbishing keeps the end product out of the landfill

What happens when a fuel cell reaches end-of-life? Because of our unique design, our fuel cell stacks are easily refurbished, recycled, and returned into service. We know that the platinum in our fuel cell products is the highest CO2 emission contributor.

As such, we recycle 95% of the platinum from our membrane electrode assemblies (MEAs) to ensure we lower our overall product GHG impacts.

Read more: Ballard's Commitment to Sustainability: What You Need to Know

Green hydrogen is essential

In diesel-powered vehicles, the most GHG emissions are released from the tailpipe, during the vehicle’s use. Fuel cell electric vehicles produce zero emissions from the tailpipe, so the most GHG emissions are produced earlier in the life cycle, during the production of the hydrogen fuel. For maximum decarbonization, it’s important to look at the resource requirements of generating the hydrogen.

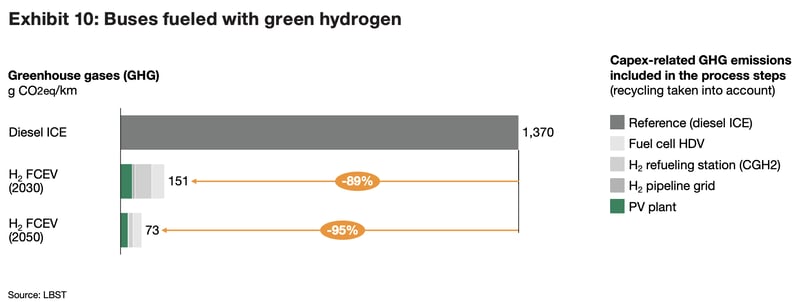

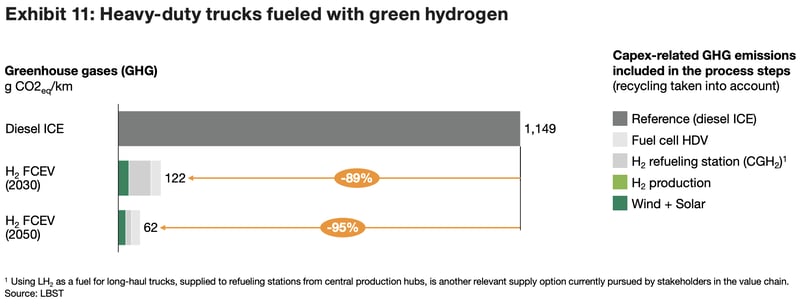

A newly released report from the Hydrogen Council, Hydrogen Decarbonization Pathways, found that, when fueled with green hydrogen, fuel cell-powered transit buses and heavy-duty trucks produce significantly less GHGs than diesel alternatives. The report identifies buses and heavy-duty trucks as two of the eight pathways that showcase how hydrogen can support the energy transition.

Source: Hydrogen Decarbonization Pathways: A Life-Cycle Assessment

Source: Hydrogen Decarbonization Pathways: A Life-Cycle Assessment

For transit buses, GHG emission reductions of close to 90% and 95% can be achieved by 2030 and 2050 respectively, compared to diesel buses. For heavy-duty trucks, GHG emission reductions of close to 90% and well above 90% can be realized by 2030 and 2050 respectively, compared to diesel-powered trucks.

The report predicts that the global energy grid mix will continue to improve from 2030 to 2050, thereby driving down GHG emissions from both the transport of hydrogen and the auxiliary energy supply needed to operate hydrogen refueling stations.

The Hydrogen Council’s report shows that low-carbon hydrogen is economically and environmentally feasible at scale, if the right localized approach and best practices for production are used. As the report demonstrates, the hydrogen production pathway to lower lifecycle GHG emissions requires a multi-disciplined approach.

The best approach is to leverage regional resources, and to include a combination of production pathways:

- Green hydrogen produced via water electrolysis using renewable energy.

- Blue hydrogen produced from natural or goal-derived gas along with carbon capture and sequestration.

Total life cycle sustainability

While Ballard-powered bus, truck, train, and marine powertrains generate zero emissions, we at Ballard are committed to reducing our carbon footprint and waste at all levels, through our operations and manufacturing processes. We know that our customers and other stakeholders are equally motivated. When they compare power sources for their transport systems or power infrastructure, they need to understand the complete environmental impacts of the various options.

As the data in our 2020 ESG Report demonstrates, Ballard is on a path of continual improvement in our corporate GHG footprint, and making real progress towards becoming carbon neutral by 2030.

Ballard Environmental, Social and Governance (ESG) Report 2020

As the world moves toward a future of zero-emission mobility, Ballard is striving toward sustainability across the entire life cycle of our

products. Read all about our actions in our 2020 ESG report.