Ballard's FCgen®-HPS is a high performance, high power density, liquid-cooled fuel cell stack designed to provide propulsion for a range of light-, medium- and heavy-duty vehicles.

The HPS stack utilizes Ballard's proprietary heavy-duty membrane electrode assembly (MEA) and low-cost durable carbon plates to deliver optimized performance and compelling total cost of ownership. The innovative and modular design is built for scalability and incorporates ports on both sides of the stack's end plates for flexible integration and provides stable electrical power, scalable over a wide range of operating and environmental conditions.

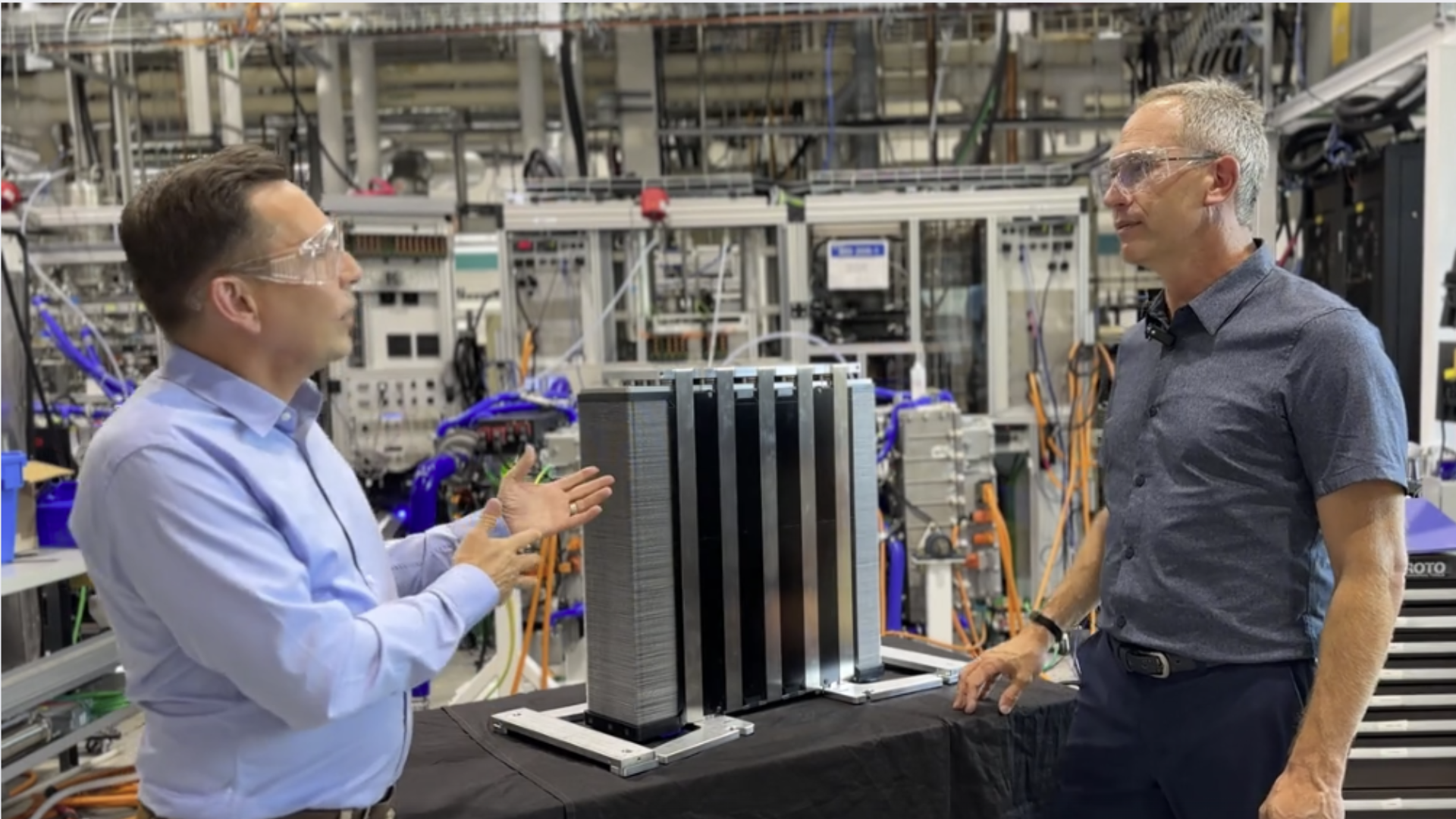

In this video, Kevin Colbow, Chief Technology Officer, and Nicolas Pocard, Vice President, Marketing & Strategic Partnerships, introduce Ballard's latest-generation high-power stack for zero-emission mobility:

FCgen®-HPS offers high power in a small package. Its optimized footprint involves a unit cell design that presents an ideal option for applications that require a high level of power output within a compact space, while cost and efficiency are optimal to provide attractive upfront and additional operating costs.

The stack has demonstrated industry-leading power output and efficiency. Its wide operating range - from -30°C to 90°C - ensures flexibility in varying real-world conditions while delivering a consistent high power output. Designed with a robust and durable structure using proprietary materials that resist corrosion and degradation, the stack's advanced manufacturing techniques deliver quality and long life.

Furthermore, the stack's life can be renewed with Ballard's refurbishment program to decrease the total cost of ownership over the application's lifetime. Sustainability is also a key concern - with Ballard offering an end-of-life process that extends the product life and reduces waste - retaining most stack components for re-use and recycling the MEA.