There is no doubt that the future of public transit and goods distribution transportation is going to be zero emission.

Diesel engines, that power our buses and heavy duty trucks, will be replaced with other technologies that don’t spew toxic fumes from the tailpipe. The health cost savings alone justify the change - more about that subject another time.

The debate is now about which technology (or combination of technologies) will become the preferred propulsion system to power our buses and heavy duty transport vehicles through streets and across towns.

No doubt some will continue touting their euphoric vision of battery power as the number one choice. The reality is, battery power alone has serious issues when used in heavy duty applications such as bus or transport vehicles.

It is simple math: the bigger the vehicle, the bigger the battery bank needs to be. Bigger batteries increase vehicle weight, reduce payload capabilities and available range.

It is simple math: the bigger the vehicle, the bigger the battery bank needs to be. Bigger batteries increase vehicle weight, reduce payload capabilities and available range.

Just imagine a battery powered dump truck.

The battery required to drive it would be as large as the payload it is attempting to transport. It is simply not a viable option.

So, how do we solve this complex issue?

Fuel Cell-Battery Hybridization Will Power the Heavy Duty Vehicles of Tomorrow

How about we put a light weight zero-emission power generating source onboard the vehicle?

This system could ensure the batteries are in a constant state of charge (improving their lifetime) while providing the power to the electric drive.

Sound like a pipe dream? It isn’t.

The reality is that this power source is available today and is being deployed in transit networks around the world.

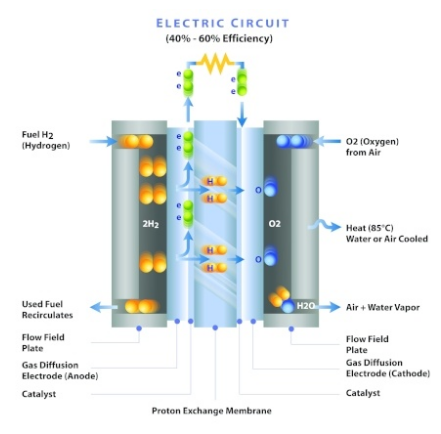

It’s called a fuel cell and it uses hydrogen to create electricity.

With millions of miles in commercial service across the spectrum of road and geographic conditions, it is the super-engine of our future.

The best part? No recharging infrastructure needs to be built along the street or at route nodes. This hybrid fuel cell-battery combination equates to a 1:1 replacement for diesel power.

However, the real question that begs to be asked is, “With all the ill effects of fossil fuel by-products why isn’t this solution more widely adopted?”

The answer is in system cost and hydrogen infrastructure.

The Facts on Cost and Hydrogen Refueling Infrastructure

The Cost Factor

Early adopters paved the way for widespread deployment of fuel cell-battery technology - as is always the case with government subsidies.

Since they first hit the road in the 1990’s purchasing costs for fuel cell electric buses have reduced by 75% and continue to decrease as more orders are being placed.

A maturing technology combined with economies-of-scale are having a tremendous impact on the capital outlay associated with implementing this clean air solution.

The Hydrogen Influence

This abundant industrial gas has been slow at being made available for general transportation use. That is why inroads are effectively being made with public transit fleets.

They have their own refueling depots. One hydrogen “station” would easily serve an entire fleet of vehicles. We are seeing situations where fuel cell transit fleets are making their refueling infrastructure available to the general public.

Until the technology is widely adopted both vehicle categories benefit from the shared utility.

Conclusion

The value proposition is appealing: no more nasties being emitted, just water vapour from the tailpipe, fuel cell electric bus costs are coming down and the result is healthier communities. In addition, fuel cell-battery hybridization compensates for the challenges that 100% battery-powered vehicles face on their own. What’s not to like about this solution?

Learn more about the benefits of hybridization for heavy duty vehicles in our free white paper below.

Join the conversation. Let us know your thoughts in the comments.

White Paper: Battery- Fuel Cell Hybrid Electric Buses

Discover the advantages of hybridization for the fuel cell drivetrain in this free white paper.