Today, everybody knows that fuel cell electric buses and battery electric buses work. They've been deployed, and they’re operating successfully around the globe.

Thanks to recent zero-emission regulations, more agencies are starting to use these buses. Many European cities are even looking to convert their fleets to 100% zero-emission.However, very few have deployed zero-emission buses on a large scale.

The challenges now are:

- How do we grow a zero-emission bus fleet at scale?

- How do we grow our fleets from 10-20 zero-emission buses to hundreds per depot?

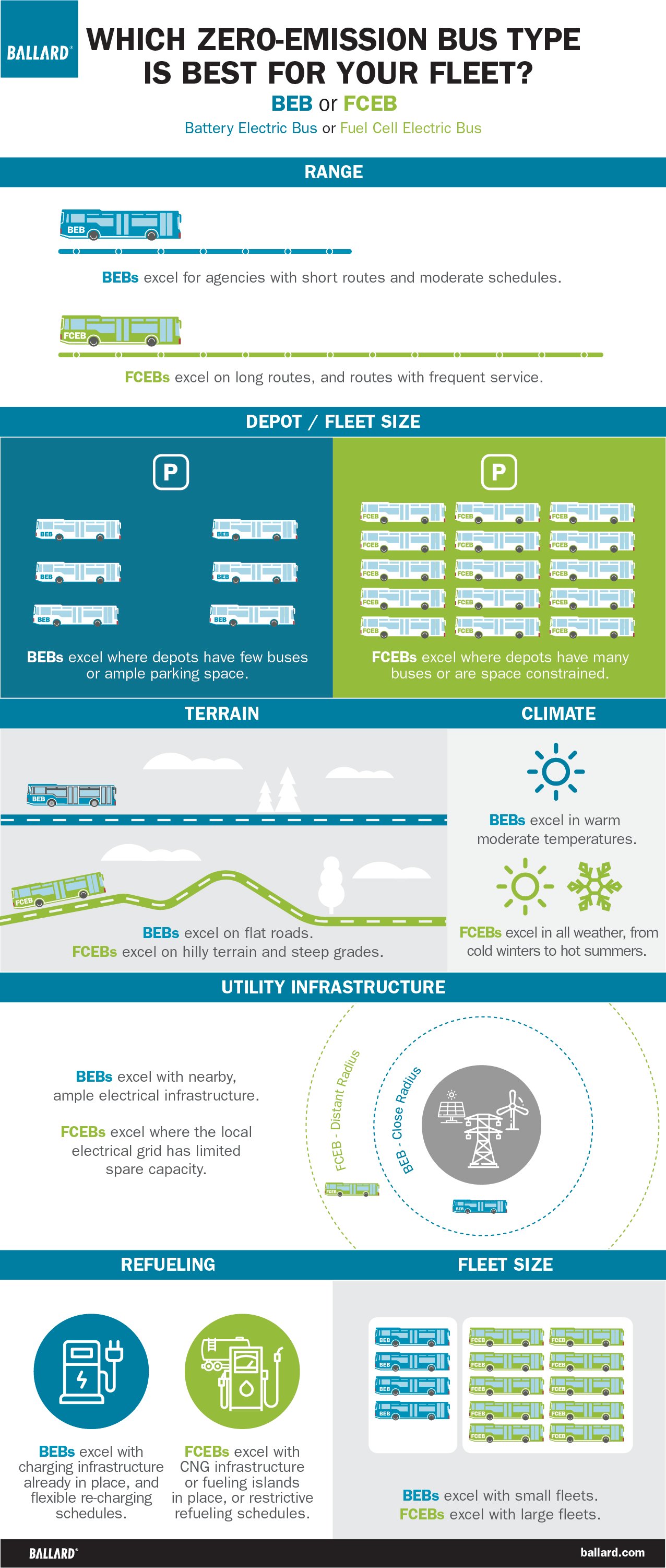

In this infographic, we break down the variables that come into play when scaling up your zero-emission bus fleet. Here’s a look at the situations in which each bus type works best.

In this infographic, we break down the variables that come into play when scaling up your zero-emission bus fleet. Here’s a look at the situations in which each bus type works best.

(Click infographic to enlarge.)

Let’s look closer at four key challenges—and the solution—to achieving large scale deployment of zero-emission buses.

Top 4 Challenges to the Successful Scalability of Zero-Emission Buses

1. Navigating depot space

Today, a typical bus depot holds anywhere from one to three-hundred diesel or CNG buses. Due to limited space, these buses are generally parked very close together, as compactly as possible.

A challenge transit agencies will face with a battery electric bus (BEB) fleet is that BEBs require ample physical depot space. The space needs to be available for at least four-to-six hours for these buses to fully charge their batteries.

Fuel cell electric buses (FCEBs) are treated in the same way as diesel and CNG buses. They don’t require the charging infrastructure that takes up that extra space. FCEB’s are quickly refuelled and then parked tightly in the same space as diesel and CNG buses.

Aberdeen Fuel Cell Electric Bus Fleet

Aberdeen Fuel Cell Electric Bus Fleet

2. Installing electrical infrastructure

To keep a fleet of battery electric buses operational, access to megawatts of power is required in order to recharge them. This will likely require a utility upgrade, including the installation of new power lines, and potentially a new substation. The grid capacity analysis alone could take a year or more to complete, so speaking with your local utility provider is essential as you begin your diligence process.

When assessing BEBs, it’s important to not only consider the infrastructure you need inside of the depot to charge the buses, but also the power infrastructure outside of the depot to feed your chargers enroute.

FCEBs don’t require any major utility upgrades. In many cases, agencies can install hydrogen refueling infrastructure with a similar footprint to CNG refueling. Different flexible and scalable options, from gas or liquid delivery, to on-site production are available to meet specific site and operator requirements.

To learn more about refueling with hydrogen, see Why Hydrogen Fueling Stations Are Gaining Global Momentum.

3. Managing operational changes

Agencies are well versed in the processes around managing a fleet of diesel or CNG buses. Today, the buses return to the depot, they’re washed and refuelled, and then they’re parked.

Route schedules can demand that buses return to service only a few hours after returning to the depot for cleaning and refuelling. The logistics involved in ensuring the buses keep to their schedules can become complex—especially given the limited space of a typical depot.

With battery electric buses, transit agencies will have to change their operational processes. For example, they’ll have to accommodate for charging times of four-to-six hours. They’ll have to implement new processes and systems to monitor whether the battery is fully charged before the bus can return to service.

Fuel cell electric buses have the exact same processes as conventional buses. The FCEB arrives, it's cleaned, filled up in less than 10 minutes, then can be parked at the same location—or easily put back into service if needed. FCEB can also be parked along or in-between conventional buses.

The same refueling facility can accommodate diesel, CNG, and hydrogen refueling islands, all next to each other in the same location.

Bus refueling station at SARTA (OH) with CNG and hydrogen dispensing

Bus refueling station at SARTA (OH) with CNG and hydrogen dispensing

Around the world today, there are CNG depots that provide fuel for hundreds of buses. CNG’s success proves that you can refuel hundreds of buses using a “gas” as a fuel. It’s been easily done with CNG, and it can be just as easily be done with hydrogen.

For in-depth info on large-scale hydrogen bus refuelling, see this report by the European Fuel Cells and Hydrogen Joint Undertaking.

4. Understanding true costs

Whether you choose fuel cell electric or battery electric buses, or a combination of both, you’ll have to plan for infrastructure improvements and their associated costs. But beyond infrastructure, there are other key costs you need to consider.

One of the most challenging costs to assess is the cost of electricity.

Today, transit agencies can accurately calculate their yearly diesel and CNG fuel costs. With certainty, they know what the cost per gallon or liter is, and they know how much buses consume. Cost certainty is essential for annual budgeting and planning.

When you bring electricity into your operating costs, the process of predictability can become very complex and difficult to optimize. The price of electricity varies greatly, depending on the time of day, and day of the year. If you want a lot of power, at one location, during peak times of the year, you’ll pay more.

These variables make it difficult for transit operators with BEBs to accurately budget for yearly electricity costs.

In contrast, hydrogen fuel is exactly like CNG or diesel. The price is fixed over a period of time, and you pay in dollars per kilogram. Knowing that a bus typically needs 20 to 30 kilograms of hydrogen per day makes budgeting for the year much more accurate.

To learn more about hydrogen fuel, see What Is the Future of Hydrogen Technology?

What else might influence cost?

The issue of competition. In most jurisdictions, you might only have one (to-three) electricity providers. This situation is a virtual monopoly and makes it difficult, or impossible, to negotiate price concessions.

When dealing with hydrogen fuel, you can put out a tender for companies to supply you with hydrogen, or even operate your hydrogen station. There are a variety of companies that will compete for the opportunity, which keeps the price of the fuel down.

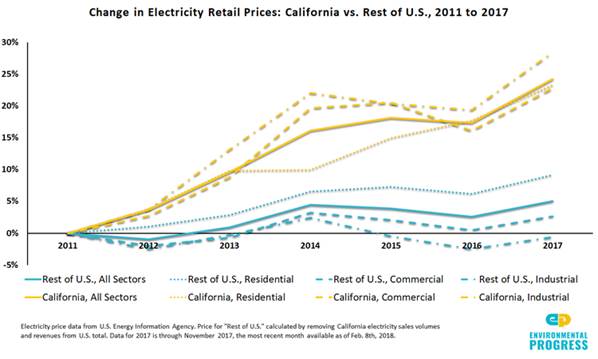

Finally, the price of electricity is always increasing. There are very few countries in the world where the price of electricity has gone down. So there’s no reason to think it will go down in the future.

In fact, with climate change, the grids are becoming more and more stressed. Events like massive fires (such as those in California) or extreme cold put a tremendous stress on the electrical grid. This invariably leads to higher electricity distribution costs.

Graph showing the increase in electricity cost in California compared to the rest of the US from 2011-2017.

Graph showing the increase in electricity cost in California compared to the rest of the US from 2011-2017.

In contrast, the price of hydrogen is going to go down. It’s the simple economic principle of supply and demand: as the volume of production increases, there will be more demand and more supply — leading to reduced costs.

Hydrogen can be sourced from fixed assets with zero fuel cost. These include PV or wind power through electrolysis, and a variety of low, zero, or even carbon-negative feedstocks through reformation. Diversity and competition are basic market forces which drive down price, and increase supply chain stability.

How to assess the cost of your zero-emission bus system

Risk mitigation strategies are essential for any transit agency. Here are two factors to consider as you design your next system:

1. Diversity of energy delivery systems. We advocate that transit agencies pilot both battery electric and fuel cell electric technologies.

Only then, can you actually do a live assessment of actual cost “at depot scale.”

2. Availability of service. Assess each alternative in the event of catastrophic storms or natural disasters, like fires or earthquakes. If the grid goes down, you can still have buses on the road, as your fuel cell electric buses are refueled from your hydrogen depot.

Key Takeaways

The zero-emission bus revolution is coming fast. Now, it’s up to cities, transit agencies, and operators to properly evaluate fuel cell electric buses and battery electric buses.

While each type has benefits, we believe that, at scale, hydrogen lowers the risk for transit agencies because:

-

Depot space and refueling process will be less of an issue.

-

You’ll have better control of your costs.

-

Major electric infrastructure requirements will be reduced.

The result will be a smoother transition, which will benefit agencies, cities, and communities alike.