The Fraunhofer Institute for Wind Energy Systems (IWES) operates open-technology test platforms - including Hydrogen Labs - for the qualification and optimization of electrolyzers, hydrogen-consuming units, and parts of the infrastructure. Two of the three Hydrogen Labs utilize Ballard's FCwave™ fuel cell modules.

Research organization Fraunhofer has set up three new Hydrogen Labs in north and east Germany, focusing on testing the entire Power-to-Hydrogen-to-Power value chain, including the long-term stability of materials and components under dynamic operating conditions. Partially powered by Ballard's FCwave™ 200kW fuel cell, the labs work as a digitally linked infrastructure with advanced capacity for testing electrolyzer and fuel cell systems up to 26MW - specifically to examine and qualify their efficiency and performance with renewable energies.

The hydrogen labs's research focus

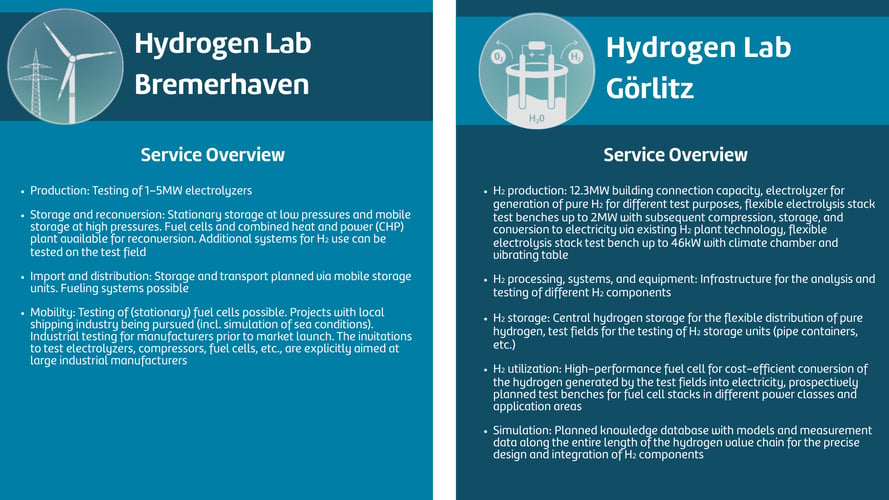

At Fraunhofer's Hydrogen Lab Leuna, the lab's integration into a chemical industry site enables practical testing of defossilization processes in the chemical sector; while the Hydrogen Lab Bremerhaven focuses on the coupling of hydrogen production with wind energy generation and investigating the grid's compatibility with electrolyzers. This helps ensure energy security even with a high share of renewable energy in the grid.

Decarbonization of the manufacturing industry is the central focus of the third Hydrogen Lab in Görlitz. Prototypes from every stage of the Power-to-X-to-Power value chain can be tested and complemented by insights into relevant production processes through collaboration with the Fraunhofer Institute for Machine Tools and Forming Technology (IWU).

The transformation of energy-intensive industries is a key component of the energy transition. Hydrogen plays a central role in this process.

The Görlitz lab is emerging as a pioneering research and development platform that actively supports the transformation of energy-intensive industries by mapping and investigating the entire Power-to-Hydrogen-to-Power value chain – from electrolysis to reconversion into electricity.

Fraunhofer considers the Görlitz facility as a central pillar of regional structural change that serves as a best practice model. Located at Siemens Energy's facility, where a multi-strand testing environment is currently being constructed, the lab benefits from the site's combination of electrolyzers, pipeline systems, storage units, and fuel cells, allowing for testing of individual components under real operating conditions – without the need to rebuild the entire infrastructure for each project.

Ballard provides the power with FCwave™

At the Görlitz lab, Ballard delivers the fuel cell system consisting of four FCwave™ 200kW modules, process cooling subsystems, controllers, and DC/DC and DC/AC converters. The 800kW fuel cell system will be installed and commissioned at the Fraunhofer Hydrogen Lab on Siemens Energy's Görlitz site and has the capacity to be expanded up to 2.4MW.

As well as serving as a reconversion unit, it is also a demonstration of integration into industrial energy systems - including process cooling subsystems and power conditioning.

In addition to Görlitz, Ballard's involvement in the Bremerhaven lab includes a FCwave™ module deployed as a backup power solution, contributing to energy security and grid stability in scenarios with a high share of renewable energy. Among other things, Bremerhaven also investigates hydrogen reconversion for peak load management and grid-supporting applications.

The Bremerhaven site will additionally focus on the integration of hydrogen production, storage, and use with the aim of developing a local hydrogen economy.