Caterpillar, in collaboration with Microsoft and Ballard Power Systems, has been recognized for its work in datacenter hydrogen fuel cell technology, winning the ‘Systems Development and Integration’ award at the U.S. Department of Energy’s (DoE) 2024 Hydrogen Program Merit Review Awards.

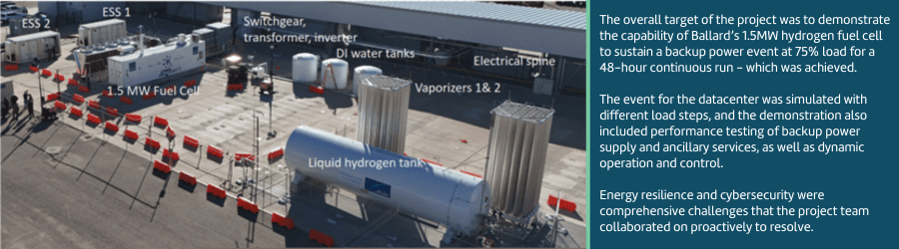

The Ballard Power Systems-supported project has successfully demonstrated its megawatt-scale fuel cell platform at Microsoft’s Cheyenne, Wyoming, data center. The 1.5MW fuel cell and battery microgrid solution showed increased resiliency and lower carbon intensity, providing applicability beyond standby, over a simulated 48-hour outage.

The industry acknowledgement arrives as the data center sector faces mounting pressure to address its soaring energy needs with sustainable solutions. Hydrogen fuel cells can help meet reliability and environmental goals, especially as backup power.

Experts from Caterpillar’s Electric Power team led the project, providing system integration, power electronics, and microgrid controls, with support from Ballard – who delivered the 1.5MW fuel cell platform.

The DoE's National Renewable Energy Laboratory (NREL), Linde, and McKinstry partnered in this project to demonstrate a first-of-a-kind megawatt-scale stationary fuel cell to generate zero-emission electric power while meeting the stand-by requirements of a modern data center.

Supported and partially funded by the DoE under the H2@Scale initiative, this three-year project demonstrates Ballard’s fuel cell system powered by liquid hydrogen. The goal is to prove that the fuel cell and battery microgrid solution is a safe and capable option for powering data centers, with applicability beyond stand-by.

Project phases: from concept development to demonstration

The project’s kick-off phase established the requirements for safe and successful data center operations. The team also evaluated the existing regulations and fuel cell market opportunities.

The next phase focused on understanding the necessary components, control strategies and cybersecurity assessment. Simulations and testing cycles provided performance data, which the team used to define the fuel cell size, including balance of plant, hydrogen storage capacity, and related equipment.

The building and testing phase began with defining the bill of materials and initiating the parts procurement process. Various benches and testing procedures were established to evaluate the developed control procedures and sub-systems.

Test cycles ranged from basic software communication checks to demonstrating a 48-hour data center backup operation cycle, as well as quality performance, and durability and reliability tests over a 150-hour timeframe.

The final six months of the demonstration project involved system installation, plant commissioning and debugging. This was followed by a two-month demonstration during which real-life data was collected. Despite the apparent short run-time, the demonstration is equivalent to up to 15 years of performance for a diesel genset at a data center.

The project underscores the rising demand for sustainable solutions for data centers. The partnership's demonstration provides valuable insights into fuel cell system capacity and capability to support multi-megawatt data centers, ensuring uninterrupted power supply to meet 99.99% uptime requirements - leveraging the most innovative digital infrastructure effectively, efficiently, and at scale.