Tyler Ladd, Director of Power Engineering at the Southeastern Pennsylvania Transportation Authority (SEPTA), is a key contributor to the agency's transition to a zero-emissions fleet. SEPTA is one of the largest transit systems in the United States, serving five counties in the greater Philadelphia area and connecting transit systems in Delaware, New Jersey.

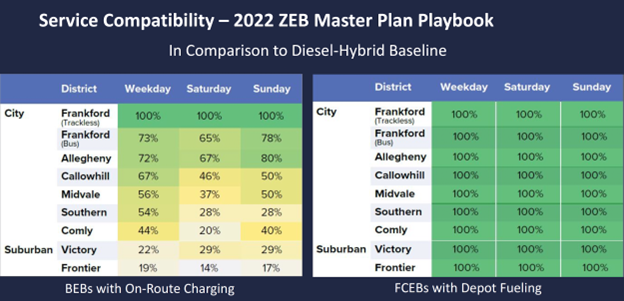

Tyler’s team has been integral to SEPTA’s transition efforts since 2016, as the agency has explored zero-emission technologies from an infrastructure perspective. In this interview, Tyler explains how fuel cell electric buses performed best when evaluated against SEPTA’s key criterion of service impact.

What is your team's role at SEPTA?

My team is responsible for the design, construction, and maintenance of all of SEPTA’s electrical infrastructure. That includes providing power to our different modes of service in addition to all our stations, shops, and other facilities. My team is involved, in some form or fashion, with all the electrical design and construction of those services.

As your transit agency is moving to a zero-emission future, what are your thoughts concerning the available technologies - battery electric or fuel cell electric battery buses?

In our analysis, the number one criterion we’ve focused on is service impact. We want to make sure that as we're evaluating different technologies, we're not doing something that's going to impact the rider experience or impact the service that we are here to provide for our communities. We've found definite pros and cons between the different technologies, whether it’s battery electric or hydrogen fuel cell, which we’re still exploring and trying to understand their place in our system fully.

What we're finding, from our early analysis, is that vehicle range is a significant consideration for our agency. We're seeing the fueling time for a fuel cell electric bus being 10-12 minutes, which mimics our diesel-hybrid fueling operation. Then we see range data from other transit agencies, where buses get 250-300 miles from a single fill. This, again, is directly comparable to how we use our diesel-hybrid buses today.

Conversely, our analysis on the battery electric side shows that for a charge of three to four hours, you're getting 150-200 miles of range. The data confirms there's a significant service impact between those two technologies. We are in business to provide transit service to our ridership, so when we look at the technology from a vehicle availability perspective, the fuel cell solution serves our needs better.

What are the next steps in your zero-emission journey?

The next step in our zero-emission program is test implementation. We have an order with New Flyer to purchase 10 40ft fuel cell electric buses. We expect those buses on the property in late spring/early summer of 2024.

To fuel the buses, we have signed a contract with Plug Power to purchase one of their mobile liquid fueler systems. The site work for the fueler is beginning construction now, and we received delivery of the fueler at the end of 2023. This allows us to commission and test it to have it ready when the buses arrive.

Those buses, combined with the fueler, will become the backbone of our testing program, which we expect to start this summer. We want to put the 10 buses through their paces to validate the data we're seeing from other agencies and to confirm that their experiences match up with our expectations.

What are the lessons learned from your evaluation process?

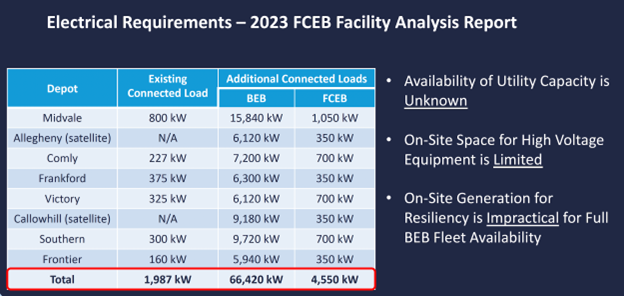

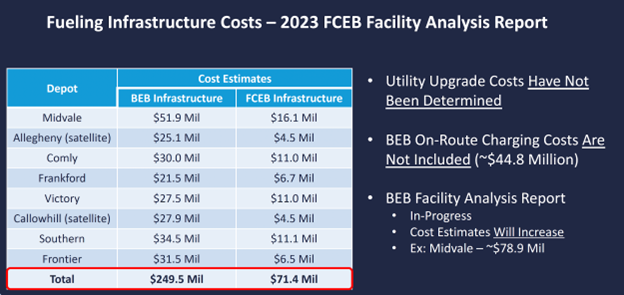

I would say that the key lessons learned so far have been centered on the infrastructure requirements when comparing battery electric and fuel cell buses. When we look at the improvements and upgrades to accommodate a battery electric fleet in terms of equipment size and footprint, utility capacity, and equipment availability, it becomes a daunting exercise very quickly. The size of electrical services we're talking about, in some cases, rivals what we see on our other modes, whether subway or railroad, which is a little unusual to see at a bus depot level.

Conversely, on the fuel cell side, we see that the electrical upgrades are primarily minimal. In many cases, we have the available capacity on-site today to accommodate any additional electrical load. For the locations where we don't have the capacity, the upgrades are relatively minimal. Speaking with the utilities, the upgrades can be easily accomplished in a much shorter timeframe. So, when we compare the two technologies from that perspective, it has been very eye-opening.

A lot of our analysis has been focused on the infrastructure capital costs. For battery electric technology, we're seeing cumbersome electrical loads that require more extensive infrastructure and expensive charging equipment. This is not the same for the fuel cell side. There’s simply less equipment; it's smaller by association and cheaper to implement.

When we start looking at the fueling or charging equipment costs, a fueling station for 100 buses is a clearly defined solution and the standard for many transit agencies. On the battery charging side, there's more variability in the number and type of charging cabinets and the charging method, whether Pantograph or plug-in.

As your fleet increases, so do the cost components associated with it. The required infrastructure and cost increase exponentially as battery electric fleets scale up. Then on top of all that, most of our facilities are space-constrained. Finding space on-site for a lot of the charging equipment becomes challenging. Not only is space a limitation, but the site might also require structural or facility upgrades to accommodate a lot of the additional electrical charging equipment needed to support battery electric bus technology.

What advice can you share with other transit agencies that are considering zero-emission buses?

We've talked with several other transit agencies that are ahead of us in this process to learn from what they've encountered. A couple of big takeaways are:

- Make sure that you communicate with all the relevant stakeholders, both internally and externally.

- Have everyone on the same page about why your organization is approaching this transition and the future of your transit agency. Agree on a defined set of criteria, as there will need to be compromises. Decisions have impacts. You need a clear lens through which to evaluate these impacts.

- Your priority structure really helps the decision-making process. For example, if “impact to service” is your number one criterion, or if “cost” is number one, then those criteria will lead you in a specific technology direction. Whereas if other potential benefits are more important, you might be led in another direction.

When we start talking about different technologies, the pros and cons, something that sometimes gets lost in the discussions is the tremendous benefit this transition will have on our riders, our employees, and the health and well-being of our communities. We're finding that every diesel-hybrid bus that we're able to take off the streets is making people's lives better - immediately. That's critical. Both battery electric and fuel cell technologies will get you there, either sooner or later, depending on your approach. We want to maintain sight of why we are doing this - we will make people's lives better beyond what public transportation already does.