Servicing the communities in eastern Los Angeles County and its surrounding areas, Foothill Transit Agency's fleet of 359 buses covers a route network of 327 square miles. With an annual ridership of nearly seven million passengers, Foothill depends upon reliable and efficient buses that can keep pace with the high utilization rate required by a large transit agency.

Rolando Cordero, Director of Maintenance and Vehicle Technology, and his team at Foothill, are driving the agency's transition to zero-emission operations - introducing both battery electric and fuel cell electric buses into service. In this interview, Roland discusses the benefits of a fuel cell bus over its pure battery counterpart in maintaining efficient passenger services and uninterrupted depot operations.

Foothill's fleet consists of 359 buses, of which 307 are powered by compressed natural gas (CNG), 19 are battery electric, and 33 are hydrogen fuel cell-powered. What are your thoughts and experience with zero-emission vehicles?

Over the last 10 years, we've gained a lot of experience operating electric buses on our routes. We quickly found that a pure battery electric solution has challenges, mostly around its limited range. We were told that a 440kWh battery pack had a range of 251 miles, but in reality we could only achieve 150 miles on a single charge. That's presented significant operational complications - even the simple task of moving buses around in the yard to charge became a challenge.

Also, we haven't been able to interline because of the limited range of these buses - some of our routes are over 200 miles long. Interlining is important for efficient operations because it allows you to operate one bus on different routes. This means you can complete one route and then send that bus and driver out to service another route, rather than returning the bus to the yard to recharge and send another bus out.

We engaged the services of Burns McDonnel Consulting to prepare a study on how the agency can electrify our fleet as we wanted to understand the implications of transitioning to a 100% battery electric fleet by 2030. Their report demonstrated it would cost us over $120m to make it happen, while it also identified that we simply don't have enough space in our bus yards to accommodate the required infrastructure. The reason for this is that battery electric is not a 1:1 replacement - it's 1.5:1. We would have to increase our entire fleet to more than 500 buses, and we simply don't have space for that.

Another layer of complexity is properly monitoring battery electric bus performance across a series of metrics. Things like watching the drivers and making sure that they are operating the buses as efficiently as possible, or purchasing electricity at certain times of the day.

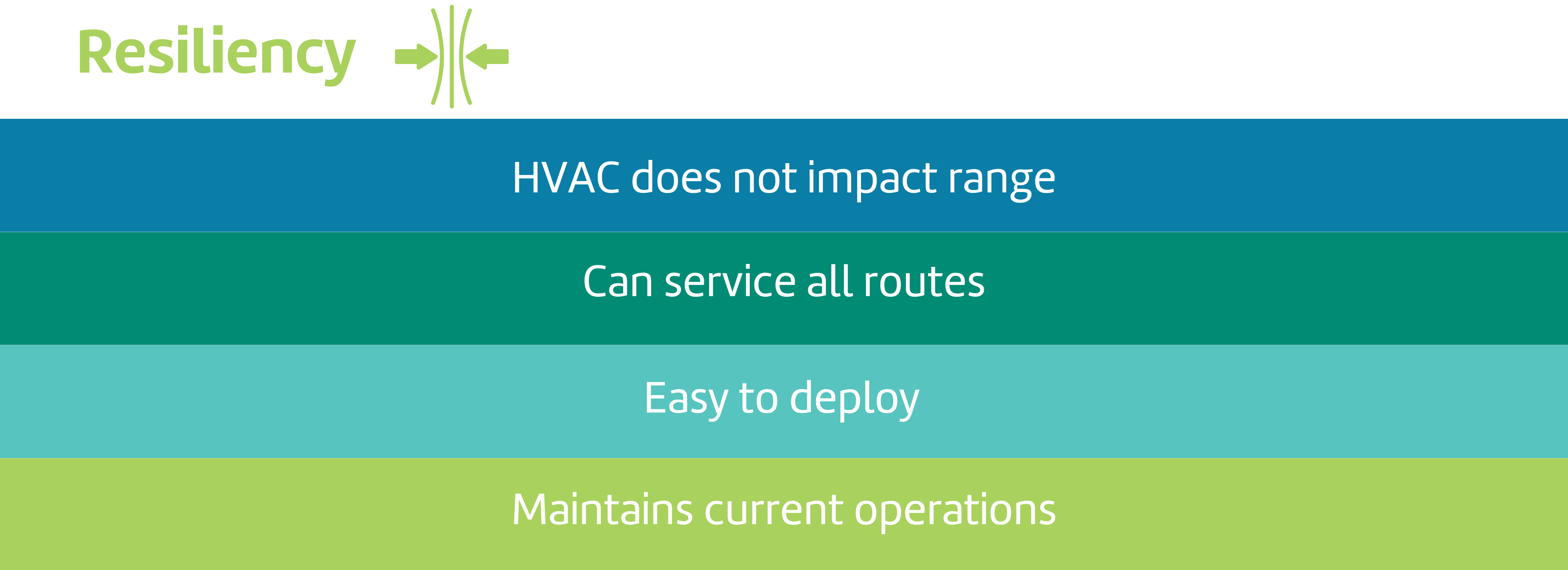

Our hydrogen fuel cell buses operate in the same way as our CNG fleet. Refueling is the same - it takes about eight minutes to fill the tank. In comparison, battery electric buses take up to four hours to fully recharge, depending on the initial state of the battery when the bus is returned to the depot. With a fuel cell electric bus, you are delivering your service to the community the same way you would with CNG, while achieving zero-emissions. For us, it is the easiest way to transition.

What type of hydrogen refueling infrastructure have you implemented?

We built our first hydrogen fueling and dispensing infrastructure at our Pomona bus yard where we installed a 25,000-gallon liquid hydrogen storage tank. The liquid hydrogen is then pumped into one of two vaporizers, which converts it into a gaseous state. That gaseous hydrogen is then saved into the storage vessel and is dispensed accordingly.

Interestingly, we can dispense from the vessels, but if there isn't enough gaseous hydrogen stored in the vessels, we can dispense from the vaporizers - so there is no downtime while we are preparing the fuel.

Foothill has been operating battery electric and fuel cell buses for some time now. What is your experience of performance and availability? Are there any types of conditions that affect service?

With a battery electric bus, traffic flow has an impact. Not only that, but the type of terrain you operate within and the weather have an effect on performance and availability. Luckily, we are in California, where we are not impacted by extreme cold temperatures like agencies in the Midwest and East Coast. Battery electric buses can lose up to 50% of the stored energy to maintain a comfortable interior environment for the riders - heating up the cabin takes a lot of energy. With hydrogen fuel cell buses, there is no impact in terms of traffic flow, route elevation changes, or the weather. Again, it's like operating a CNG bus.

Fuel cell buses are electric buses. The difference between the two technologies is that in a 100% battery electric bus you have a high capacity 440kWh battery pack. In a fuel cell bus, you have a smaller battery pack with a fuel cell that creates electricity through a chemical reaction between hydrogen and oxygen that recharges the batteries and acts as a range extender.

What are the most significant lessons that you've learned in Foothill's transition to zero-emission operations?

I would say that I was disappointed with a pure battery electric solution. It really does impose range limitations on the buses. I thought they would perform better - especially in our climate conditions. We realized that in order to extend the range of the electric bus, we had to install in-route charging systems, and that's a very costly predicament. Our studies indicated the capital investment to build a charging station was up to $700,000. One of the positive lessons we learned is that you have to install two systems - for redundancy in case one of the charging stations breaks down. If not, you leave your bus stranded. With hydrogen fuel cell buses you don't have such complications.

Speaking of complications, there have been a lot of, what I call, cottage industries with technologies designed to improve the battery electric performance for public transit. People are talking about microgrids or using battery storage to control the cost of charging your buses. Then there are “charge management systems” that are required to optimize all the different systems for recharging the buses. Things like - how much charge does the bus really need to get redeployed? What is the cost of electricity at the time of charging? How many buses are being charged simultaneously, and where are they positioned within the depot’s charging array? There are many moving parts that need to be controlled in the battery electric recharging ecosystem. You simply don’t have that complexity with fuel cell buses.

The only concern we have right now for the fuel cell technology is the cost of hydrogen. We need to reach a point where the cost per kilogram is comparable to what we pay for legacy fossil fuel or battery electric. We're paying probably twice as much to fuel our hydrogen buses versus charging our electric buses. That's the only downfall in terms of hydrogen.

How would you advise a transit agency that's considering moving to zero-emission buses?

First off, look at what other transit agencies have been piloting. Understand the different technologies, what they've learned, and what are the pluses and minuses of each solution. I encourage you to read as many articles on the subject as possible to educate yourself on the differences between hydrogen fuel cell and battery electric.

It is also very important to educate your shareholders and transit agency executives. You need to take into consideration what's good for the transit agency and implement a solution that properly fits your operation. As you can imagine, there are many influencing factors. As such, educating your shareholders on the difference between battery electric and hydrogen fuel cells will help your agency decide the right path to a zero-emission transition.